Minimized downtime of expensive drilling equipment

TRACTO reduced the time to diagnose and apply fixes to drilling rigs by 30-50% using Elastic Observability.

Improved drill rig research, development and inventory expansion

Using the drill rigs performance data the company could expand their inventory of sensor-equipped rigs thanks to the use of adding storage capacity on Elastic Cloud.

Reduced the impact of drilling on transportation infrastructures

Reduced downtime helps customers complete projects faster and more seamlessly, minimizing the impact on drivers and pedestrians with the use of Elastic.

Monitoring equipment performance data to minimize downtime and roadway disruption with Elastic Observability

Based in Germany, TRACTO GmbH is a global pioneer of trenchless technology. Its equipment enables the installation of underground pipes and cables by drilling horizontally beneath the surface. This approach eliminates the need to dig up roadways and sidewalks, reducing disruption to drivers, pedestrians, and other road users.

The company has about 600 employees with customers worldwide in the utilities, energy, and waste management sectors. Most recently, it has seen fast-growing demand from electric vehicle clients wanting to expand their charging point networks.

Interruptions to road-related engineering projects can be very costly for our customers. Our drill rigs are a critical component to the successful and timely completion of work, so monitoring and maintaining this equipment is a top priority for our customers.

To track drill rig performance, their equipment includes digital sensors that measure statistics such as torque, thrust, and drilling fluid pressure. Previously, this data was sent online to a table storage database on the Azure cloud platform for analysis.

This approach presented multiple significant challenges. Primarily, there was no way to buffer data on the rigs when there was a weak internet connection. This resulted in missing data sets which prevented the delivery of a complete diagnosis — especially if an issue occurred at the time the connection dropped — and led to added time to diagnose and fix problems.

Additionally, the analytics team was constrained by table storage, which greatly limited data extraction and visualization. As the business added more rigs, sensors, and data, it became apparent that a change was needed. With guidance from consileo, TRACTO chose Elastic Observability deployed on Elastic Cloud, as it alleviated connectivity issues thanks to the built-in fallback options of Elastic and the sophistication of the analysis tools.

Unleashing better insights into equipment performance

To overcome previous buffering issues, TRACTO aggregates sensor log files with Elastic Observability. Each drilling rig sends about 40 data points every second, "With Elastic Cloud they no longer have to worry about the growth in data volumes," says Fischer. "They can scale up to accommodate new rigs as they add them to the system."

Elastic Observability provides TRACTO with a single pane of glass for storing logs, metrics, uptime data, and other drill rig measures. With Elastic, they now have detailed insights into the behavior of their equipment in the context of the project environment.

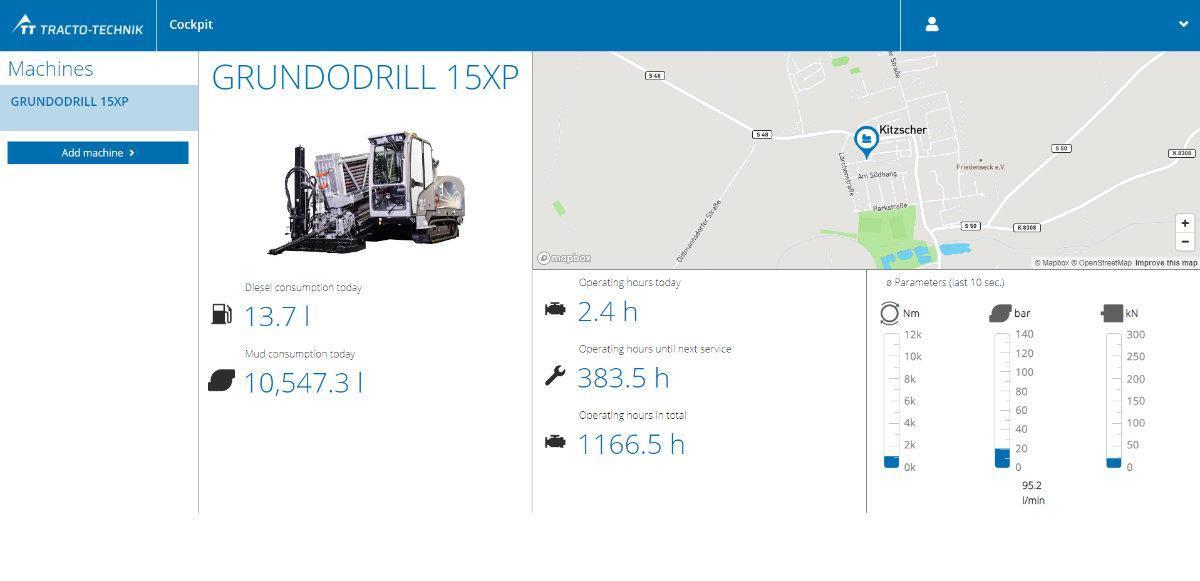

The company has also deployed Kibana dashboards for different groups of end users for simplified data visualization. Each dashboard contains a set of relevant key information for a specific group of users. Technical teams use dashboards for deep dive analysis. A customer-facing dashboard called Cockpit gives clients a simplified view of rig performance.

Caption 1: Example of rig performance dashboard on Cockpit

Elastic Observability on Elastic Cloud enables us to gather data from our equipment without buffering, combined with the super-fast query times Elastic delivers for gathering data. We can now determine and fix problems much faster based on deeper insights into our rig data.

Reducing equipment downtime, accelerating projects

TRACTO can now accurately observe drill rig performance and use the insights to improve the efficiency and reliability of its equipment. “Our first goal was to determine the operational hours of each drill rig. This is an essential metric for determining the durability of our equipment,” says Hamers.

The team can also perform large-scale data aggregations to determine average fuel consumption by machine type to dig deeper into the performance of specific machines. When anomalies occur, the data can be correlated with factors such as the local soil type or the weather conditions. These correlations help understand how these factors would impact performance. Drilling in Australia at 50°C isn’t the same as drilling in Sweden at -25°C as the hydraulic performance of the rig would be impacted.

In the past, we would get a breakdown alert and then spend a lot of time diagnosing and fixing the issue. By measuring so many data points with Elastic, we can now anticipate problems before they occur and relay the information to operators so that adjustments can be made on site.

Elastic helps TRACTO reduce equipment downtime and keep drilling projects running on time and within budget. The data is also being used by the company's research and development teams to refine the design of machine parts and the next generation of drill rigs.

With the use of Elastic Observability, the foundations for further data-centric customer offers and greater use of automatic machine learning processes at TRACTO have been prepared.

As the number of sensors increases and data volumes continue to grow, Hamers and the team hope to produce a remote-control drilling rig operated at a distance by a team of engineers and monitored using Elastic Observability on Elastic Cloud. It expects that this will further increase efficiencies and reduce the cost of having engineers on site, particularly in remote areas.